Enhancing Kenya Pharmaceutical Plant Security: Best Practices in Medical Manufacturing Protection

Ensuring the security of pharmaceutical plants in Kenya is vital for maintaining the integrity of medical manufacturing. As healthcare demands continue to grow, the need for robust security measures becomes increasingly important. Effective protection strategies not only safeguard physical assets but also ensure that the medicine produced meets high-quality standards. Here are some best practices to enhance security in Kenya’s pharmaceutical plants.

Access Control Measures

Limiting access to sensitive areas is fundamental in enhancing plant security. Implementing strict access control measures can help prevent unauthorized personnel from entering critical zones. Here are some effective access control strategies:

- Badge System: Introduce a badge system for employees and visitors that indicates their authorization level within the facility.

- Fingerprint Scanners: Utilizing biometric technology like fingerprint scanners can improve security by ensuring that only registered individuals can access sensitive areas.

- Surveillance Cameras: Place surveillance cameras at all entry points and vulnerable areas to monitor activities continuously.

Employee Training and Awareness

Your employees are the first line of defense in ensuring security at pharmaceutical plants. Regular training programs can enhance their awareness regarding security protocols and emergency procedures. Consider the following:

- Security Workshops: Offer periodic workshops that cover the latest security practices and threat identification.

- Reporting Protocols: Train employees on how to report suspicious activities or irregularities promptly. Encourage a culture of vigilance where everyone feels responsible for security.

- Emergency Response Drills: Conduct regular drills to ensure that all employees know what to do in case of a security breach or other emergencies.

Regular Security Audits

Conducting regular security audits is essential for understanding vulnerabilities and enhancing protection. These audits can identify potential weaknesses in the current security framework. Here are key steps in the auditing process:

- Assessment of Current Practices: Evaluate existing security measures, including physical security, personnel protocols, and cybersecurity.

- Vulnerability Testing: Engage external experts to conduct penetration testing that simulates a security breach.

- Reporting and Improvement: Develop a report that outlines findings and recommendations for improvements, implementing necessary changes swiftly.

Physical Security Infrastructure

An effective security infrastructure is crucial for safeguarding the plant from any threats. Focus on the following areas:

- Fencing and Barriers: Install robust fencing around the property to deter unauthorized entry. Use barriers to secure critical areas within the plant.

- Controlled Entry Points: Designate specific entry and exit points for vehicles and staff. These should be monitored and secured at all times.

- Lighting: Ensure that outdoor and indoor areas are well-lit to minimize hiding spots for potential trespassers.

Cybersecurity Measures

In an increasingly digital world, it’s important to address cybersecurity risks. Protecting sensitive data and systems in pharmaceutical plants is essential. Adopt these measures:

- Firewalls and Antivirus Software: Implement industry-standard firewalls and keep antivirus software updated to safeguard against external threats.

- Data Encryption: Encrypt sensitive data to minimize the risks associated with data breaches.

- User Training: Provide training on the importance of secure password practices and phishing threat recognition.

Crisis Management and Continuity Planning

Preparing for potential emergencies is crucial for maintaining operational integrity. Develop a crisis management plan that outlines steps to take during a security breach or any other emergency. Key components of the plan include:

- Emergency Contacts: Maintain an updated list of emergency contacts, including local authorities and security personnel.

- Communication Protocols: Establish proper communication channels for both internal and external parties to ensure information flows accurately during a crisis.

- Plan Evaluation: Regularly evaluate and update the crisis management plan based on evolving circumstances and past experiences.

By addressing these security measures, pharmaceutical plants in Kenya can protect their facilities, employees, and the vital medicine they produce. Creating a secure environment ensures that operations run smoothly and that healthcare delivery remains uncompromised. Engaging with best practices will not only enhance security but also build trust with stakeholders and consumers alike.

The Role of Technology in Safeguarding Pharmaceutical Facilities in Kenya

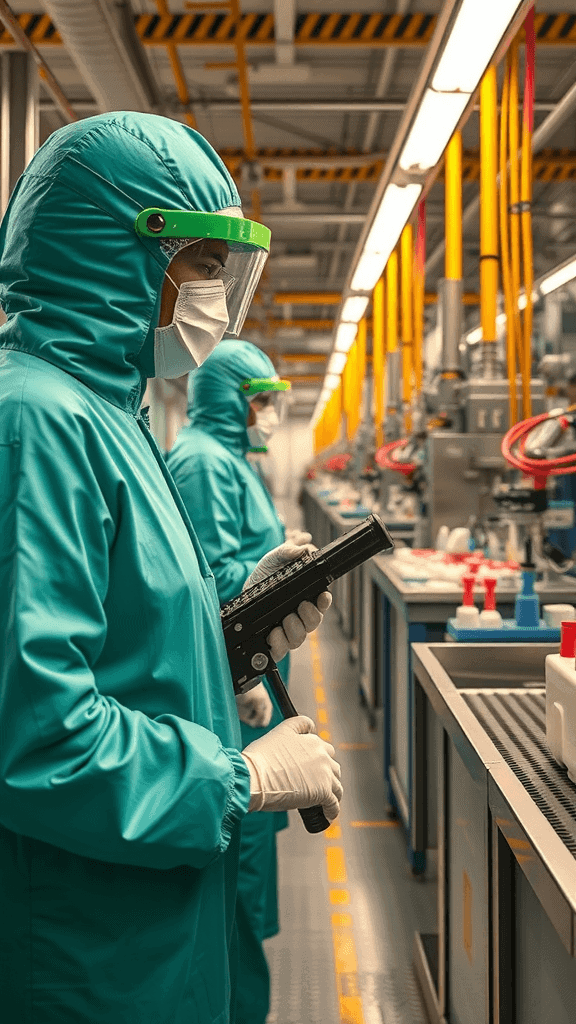

The advancement of technology plays a crucial role in enhancing the security of pharmaceutical facilities in Kenya. As the country continues to grow its pharmaceutical manufacturing capabilities, it faces various security challenges. To address these challenges effectively, technology has become an essential part of safeguarding vital resources, intellectual property, and operational integrity.

Surveillance Systems

One of the most significant technological developments in securing pharmaceutical plants is the implementation of advanced surveillance systems. Modern CCTV cameras equipped with high-definition video capture help monitor all activities within and around the facility. Key features include:

- Real-time Monitoring: Security personnel can observe live feeds from different locations around the facility, allowing for immediate response to any suspicious activity.

- MOTION Detection: Many surveillance systems now include motion detection capabilities that alert security teams to unusual movements, further increasing their readiness.

- Facial Recognition: The incorporation of facial recognition technology helps in identifying unauthorized individuals attempting to access restricted areas.

Access Control Systems

Access control technology serves as a gatekeeper for pharmaceutical facilities. By employing digital locks, biometric scanners, and keycard systems, these facilities can manage who enters and exits their premises. This technology offers several advantages:

- Identity Verification: Employees and visitors must present valid credentials which can include fingerprint scans, iris scans, or RFID cards to gain entry.

- Restricted Areas: Access control systems can restrict entry to sensitive areas, such as laboratories or storage units for high-value medicines.

- Audit Trails: The systems keep records of who accessed certain areas and when, providing a comprehensive log for security audits.

Integrated Security Platforms

Integrating various security measures into one cohesive platform offers enhanced oversight. Facilities can manage video surveillance, access control, and alarm systems from a single interface, which aids in better decision-making and response time. Features of integrated security platforms include:

- Centralized Management: Security personnel can observe multiple security inputs in one place, simplifying monitoring operations.

- Responsive Alerts: In the event of security breaches, the system can send automatic alerts to law enforcement or local authorities.

Cybersecurity Measures

As pharmaceutical facilities increasingly rely on digital infrastructure, the potential for cyber threats grows. Employing stringent cybersecurity measures is vital to protect sensitive data, including research and proprietary manufacturing processes. Essential components include:

- Firewalls and Encryption: These technologies help defend against unauthorized access and secure confidential data.

- Employee Training: Conducting regular training for employees about cybersecurity practices reduces risks associated with human error, such as phishing attacks.

IoT and Smart Technology

The Internet of Things (IoT) is making its way into the pharmaceutical sector, enhancing security at every level. Smart devices can monitor conditions in storage facilities and report issues like temperature fluctuations, essential for keeping medications effective. Benefits include:

- Automated Alerts: Sensors can send alerts if there are deviations in expected conditions, ensuring timely responses to potential risks.

- Preventive Maintenance: Regular monitoring can help predict equipment failures before they happen, adding an extra layer of security within production processes.

Leveraging technology within the pharmaceutical industry in Kenya not only ensures the physical security of manufacturing plants but also protects their invaluable intellectual assets. As threats evolve, investment in cutting-edge technologies will play a pivotal role in ensuring that pharmaceutical facilities remain secure while continuing to meet the healthcare needs of the country.

Relying on advanced security solutions introduces not only safety but also boosts productivity and trust among partners and clients. For Kenya, integrating innovative technologies will set the foundation for a robust and secure pharmaceutical future.

Conclusion

Ensuring the security of pharmaceutical plants in Kenya is imperative for safeguarding the integrity of medical manufacturing processes. By adopting best practices tailored to the unique challenges within the industry, these facilities can effectively mitigate risks associated with theft, sabotage, and contamination. Effective training protocols for staff, alongside reinforced physical security measures like access control and surveillance, offer vital layers of protection.

The incorporation of advanced technology has further transformed the security landscape. Innovations such as biometric systems and real-time monitoring solutions not only enhance safety but also provide actionable insights for continuous improvement. Automated alerts, for instance, empower facility managers to address security breaches swiftly, minimizing potential threats before they escalate.

Moreover, collaboration between government agencies, security experts, and the pharmaceutical industry is necessary to establish comprehensive security frameworks. Regular assessments and updates to security protocols ensure that pharmaceutical plants fortify their defenses against evolving threats. By fostering an environment of awareness and preparedness, stakeholders can create a resilient manufacturing ecosystem that prioritizes the safety of both products and personnel.

Ultimately, strengthening Kenya’s pharmaceutical plant security is not just about protecting physical assets; it’s about ensuring the trust and well-being of communities relying on these essential medicines. With ongoing commitment to security best practices and the integration of cutting-edge technology, the future of medical manufacturing in Kenya can remain both safe and reliable.